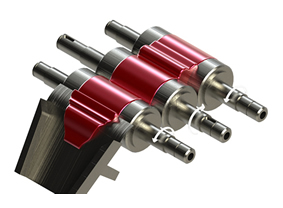

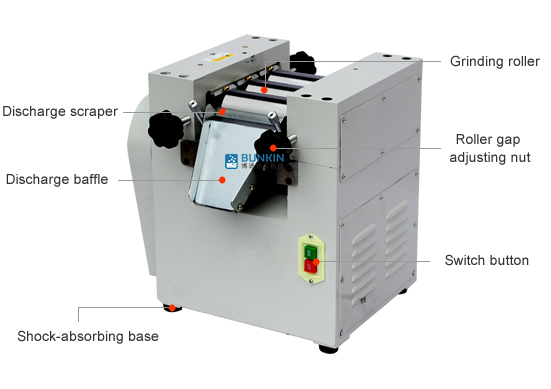

Lab three roll mill is suitable for paste or high viscosity materials that require high dispersion and fineness requirements; By squeezing the surfaces of the three horizontal rollers against each other and manually adjusting the space between the rollers, the grinding effect is achieved through friction at different speeds. Equipped with an emergency button to prevent equipment damage caused by falling foreign objects. The rollers are cast with special hard alloy, pure zirconia material can also be used.

1.Wide application range

When designing the equipment, the protrusion of the roller can be adjusted based on the material viscosity, and can be used for products with high, medium, and low viscosity.

2.Low temperature rise, stable

The roller center can be cooled with cooling water during operation, providing excellent cooling effect. Conventional temperature rise is less than 10 º, ensuring product quality.

3.Non-standard model can be customized

Can be customized with explosion-proof type; Roller material can be customized with ceramic materials such as zirconia and alumina.

Lab three roll mill consists of three rollers, installed on a rack and directly driven by an electric motor. The rotation direction between the general rollers is different, the front roller rotates forward and the middle roller rotates backward. The roller speed is fast for the front roller and slow for the back roller. The middle roller speed is fixed, and the front and rear rollers are installed on the slide with a spring device. The distance between the front roller ,back rollers and the middle roller is adjustable by using a handwheel. The material enters between the back roller and the middle roller, after compressed by the roller, material particles become finer, and then took out by the fast roller. with a scraper equipped at the end of the fast roller,material is separated from the roller and fall into the collection tank.

| Model | Power(KW) | Roller Length(mm) | Roller Dia.(mm) | Speed(rpm) | Capacity(Kg/h) | Fineness(um) | Weight(Kg) | Dimension(mm) |

| BS65 | 0.75 | 125 | Φ65 | 32/89/250 | 5-10 | 3-18(3次) | 70 | 440*420*400 |

+86 13966796215 ( Hot Line )

+86 (0)551-67707017 ( Direct Line )

+86 13966796215