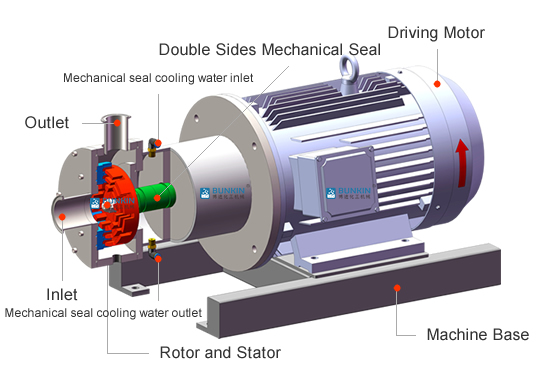

Single stage high shear mixer is a homogeneous emulsification equipment that continuously produces or circulates fine materials.The motor drives the rotor to run at high speed, which narrows the particle size of liquid-liquid and solid-liquid materials through the action of mechanical forces,so that one phase is evenly distributed to another or more phases, so as to achieve the effect of refine homogenization and disperse emulsification .It has certain applicability for medium to high viscosity materials by adding a feeding pump at the front stage. The equipment runs smoothly with low noise, and has no dead corners, material is forced to disperse and shear; It has the function of short distance and low lift conveying.【Patent NO.:ZL201820997023.8】

1. Continuous dispersion and emulsification effect are excellent, CIP design for cleaning.

2. Speed can reach 3000 rpm and can be adjusted through energy-saving and environmentally friendly inverter.

3. All stainless steel machine frame, sanitary stainless steel motor cover is optional.

4. The rotor & stator is manufactured by whole forging material in a CNC machining center with high accuracy which make it have high linear speed.

5. Double sides mechanical seal design, no leakage, safe and reliable, reduce maintenance costs.

6. The mechanical seal is designed with water shortage protection, machine can be operated for long time due to jacket cooling design.

7. Can offer various connection methods such as flanges, quick connections, SMS quick installation, etc. according to actual needs. We can customize the machine for use in special pressure and temperature environments (high and low temperature resistance).

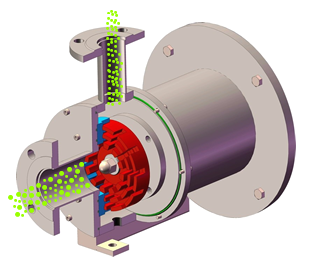

The single stage high shear mixer adopts horizontal structure; One set of rotator and stator is installed in the narrow working chamber, which can be designed as a single stage two layers or single stage six layers structure, with dual coupling between the rotators and stators.

The intermediate shaft is driven by a motor for high-speed operation, vacuum condition occurs between rotor and stator,The material is sucked into the rotor&stator cavity from the inlet of the sinlge/jacket tank, Rotor driven by the strong kinetic energy creates high linear speed,material will fly out after strong crushing, tearing, centrifugal extrusion, hydraulic friction,etc between the gap of the stator and rotor,under the action of a variety of different directions, strong turbulence is generated, and materials flow out from the outlet. it can make multiple cycle process according to requirements.

| Model | Power(Kw) | Speed(rpm) | Capacity(m3/h) | Lift(m) | Inlet | Outlet | Dimension(mm) | Weight(Kg) |

| BZ1-4 | 4 | 3000 | 2.5 | 10 | DN40 | DN32 | 677*340*348 | 90 |

| BZ1-7.5 | 7.5 | 3000 | 6 | 10 | DN50 | DN40 | 756*365*377 | 125 |

| BZ1-11 | 11 | 3000 | 11 | 10 | DN65 | DN50 | 887*405*420 | 195 |

| BZ1-15 | 15 | 3000 | 16 | 10 | DN65 | DN50 | 893*405*420 | 215 |

| BZ1-18.5 | 18.5 | 3000 | 20 | 10 | DN80 | DN65 | 937*405*420 | 232 |

| BZ1-22 | 22 | 3000 | 25 | 10 | DN80 | DN65 | 998*430*479 | 306 |

| BZ1-30 | 30 | 3000 | 32 | 10 | DN100 | DN80 | 1225*550*596 | 456 |

| BZ1-37 | 37 | 3000 | 40 | 10 | DN100 | DN80 | 1225*650*596 | 470 |

| BZ1-45 | 45 | 1500 | 50 | 10 | DN125 | DN100 | 1259*650*642 | 534 |

| BZ1-75 | 75 | 1500 | 60 | 10 | DN125 | DN100 | 1850*700*920 | 750 |

| * (Water as the medium for flow and lift data.) | ||||||||

+86 13966796215 ( Hot Line )

+86 (0)551-67707017 ( Direct Line )

+86 13966796215