The hydraulic lift basket mill integrates dispersion and grinding into one machine, suitable for wet grinding of middle and low viscosity fluids. It is an intermittent industrial production equipment, with a reasonable design of the grinding basket structure,it is convenient for cleaning, and easy for changing color ; The lifting structure uses hydraulic oil cylinders as actuators, ensuring stable lifting. using an integrated oil tank, which is environmentally friendly and leak free; This machine is an ideal dispersion grinding equipment for multiple varieties and colors.

1.High grinding efficiency, Excellent fineness

The powerful kinetic energy drives the zirconia paddle to do irregular movement of the grinding medium in the cavity, causing high-speed collisions and friction between each other, resulting in a rapid reduction in material particle size; The grinding fineness can generally reach below 10um, and some products can reach sub micron or even nano scale.

2.Easy to operate, safe

The equipment uses a cylinder as the lifting actuator, the pneumatic control valve controls the grinding device to go up, stop, and go down, stable and easy to operate; Equipped with different types of clamping devices, it can quickly fix the grinding tank to prevent displacement and safety accidents during operation.

3.Low temperature rise, stable

The tank comes with a double-layer cooling jacket,Cooling with water during operation has good effect, temperature rise less than 10 ℃; can design cooling system for grinding chamber according to needs.

4.Various of types can be customized

Can be customized with explosion-proof, vacuum sealed and other requirements; The grinding chamber can be customized with zirconia material; The equipment material can be customized with SS316L stainless steel.

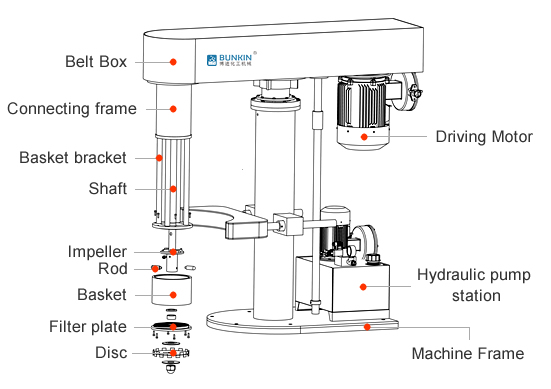

The motor drives the rod and disc at the bottom of basket to rotate at high speed during working, creating vacuum condition in the upper part of the disc and inside of the basket chamber, and the material is sucked into the grinding chamber. The rod drives the grinding medium in the chamber generates forces in all directions, causing material particles continuously collide and rub with the grinding medium, which achieve smaller particle size and narrower size range; The disc runs at high speed which generates eddy currents to extract the materials from the cavity and recycle them to the feeding part, resulting in a very significant dispersion grinding and mixing effect. the hydraulic pump drives the hydraulic plunger to go up and down, making the entire transmission mechanism and grinding device go up and down together.

The motor drives the rod and disc at the bottom of basket to rotate at high speed during working, creating vacuum condition in the upper part of the disc and inside of the basket chamber, and the material is sucked into the grinding chamber. The rod drives the grinding medium in the chamber generates forces in all directions, causing material particles continuously collide and rub with the grinding medium, which achieve smaller particle size and narrower size range; The disc runs at high speed which generates eddy currents to extract the materials from the cavity and recycle them to the feeding part, resulting in a very significant dispersion grinding and mixing effect. the hydraulic pump drives the hydraulic plunger to go up and down, making the entire transmission mechanism and grinding device go up and down together.

| Model | Power(Kw) | Speed(rpm) | Lift Method | Lifting stroke(mm) | Zirconia Beads | Capacity(L) | Limit Fineness(μm) |

| BL-4 | 4 | 0-1500 | Hydraulic | 700 | 1.2-2.0(High Purity Zirconia Beads) | 30L-100L | 0.2 |

| BL-7.5 | 7.5 | 0-1500 | Hydraulic | 700 | 1.2-2.0(High Purity Zirconia Beads) | 40L-200L | 0.2 |

| BL-11 | 11 | 0-1300 | Hydraulic | 900 | 1.2-2.0(High Purity Zirconia Beads) | 50L-300L | 0.2 |

| BL-15 | 15 | 0-1300 | Hydraulic | 900 | 1.2-2.0(High Purity Zirconia Beads) | 50L-400L | 0.2 |

| BL-18.5 | 18.5 | 0-1300 | Hydraulic | 900 | 1.2-2.0(High Purity Zirconia Beads) | 80L-600L | 0.2 |

| BL-22 | 22 | 0-1100 | Hydraulic | 1200 | 1.2-2.0(High Purity Zirconia Beads) | 150L-800L | 0.2 |

| BL-30 | 30 | 0-1100 | Hydraulic | 1200 | 1.2-2.0(High Purity Zirconia Beads) | 250L-1200L | 0.2 |

| BL-37 | 37 | 0-1100 | Hydraulic | 1200 | 1.2-2.0(High Purity Zirconia Beads) | 500L-1500L | 0.2 |

| BL-45 | 45 | 0-1000 | 液压 | 1400 | 1.2-2.0(95%高纯氧化锆珠) | 500L-2000L | 0.2 |

| BL-75 | 75 | 0-900 | 液压 | 1500 | 1.2-2.0(95%高纯氧化锆珠) | 600L-3000L | 0.2 |

+86 13966796215 ( Hot Line )

+86 (0)551-67707017 ( Direct Line )

+86 13966796215