Electric lift basket mill is an economical wet dispersion grinding equipment developed for scientific research institutions and enterprises. It can be operated for a long time with stable speed and low noise, dispersing and grinding processes are integrated in one machine, effectively reducing the fineness of medium and low viscosity materials in a short period of time.

1.High grinding efficiency, Excellent fineness

The equipment can rotate at a speed of up to 3000rpm, driven by powerful curved impeller kinetic energy. The zirconia paddle causes irregular movement of the grinding medium in the chamber, making high-speed collisions and friction between each other, resulting in a rapid reduction in material particle size; The grinding fineness can generally reach below 10um, and the liquid-liquid dispersion grinding can reach sub micron or even nanometer levels. The filter plate is processed by a whole board in a CNC center, non clogging, long service life, and reduces maintenance costs.

2.Easy to operate and clean

The equipment comes with an energy-saving inverter that can directly control the startup and speed regulation of the equipment; Equipped with an economical and energy-saving manual lifting device, which can achieve relative sealing between the tank and the lid, this way it can reduce solvent evaporation during the grinding process; The unique design of the grinding chamber allows for direct solvent circulation cleaning, and the entire machine is designed as stainless steel, which is aesthetically pleasing; Grinding time can be set according to the process.

3.Low temperature rise, stable

The tank comes with a double-layer cooling jacket, it has a mirror polished surface, beautiful and easy to clean; Cooling with water during operation has good effect, temperature rise less than 10 ℃; We can equip more tanks for one model of machine so that can deal with different colors.

4.Various of types can be customized

The lifting mode of the equipment is manual lifting; Can be customized as explosion-proof type; The material contact parts can be made of SS304 & SS316L material; If there are high temperature, high pressure, flammable, explosive, corrosive and other working conditions, detailed data must be provided and can be customized according to needs.

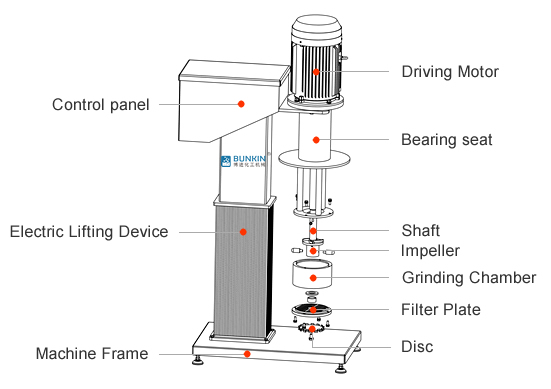

The motor drives the rod and disc at the bottom of basket to rotate at high speed during working, creating vacuum condition in the upper part of the disc and inside of the basket chamber, and the material is sucked into the grinding chamber. The rod drives the grinding medium in the chamber generates forces in all directions, causing material particles continuously collide and rub with the grinding medium, which achieve smaller particle size and narrower size range; The disc runs at high speed which generates eddy currents to extract the materials from the cavity and recycle them to the feeding part, resulting in a very significant dispersion grinding and mixing effect.

| Model | Power(Kw) | Speed(rpm) | Basket Volume(L) | Container(L) | Grinding Medium | Beads Size(mm) | Lifting Stroke(mm) | Lifting Method |

| BLS-1.1 | 1.1 | 0-3000 | 0.3L | Jacket 3L/5L | High Purity Zirconia Beads | 0.8-2.0 | 250 | Electric |

| BLS-1.5 | 1.5 | 0-3000 | 0.5L | Jacket 10L | High Purity Zirconia Beads | 0.8-2.0 | 350 | Electric |

| BLS-2.2 | 2.2 | 0-3000 | 1L | Jacket 20L | High Purity Zirconia Beads | 0.8-2.0 | 400 | Electric |

| BLS-4 | 4 | 0-1500 | 1.5L | Jacket 40L | High Purity Zirconia Beads | 0.8-2.0 | 500 | Electric |

+86 13966796215 ( Hot Line )

+86 (0)551-67707017 ( Direct Line )

+86 13966796215