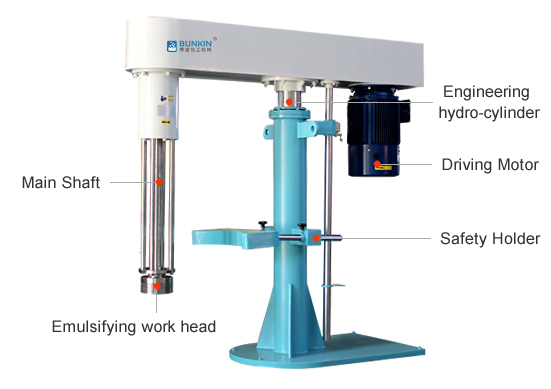

The particle size of liquid-liquid and solid-liquid materials is narrowed by external mechanical forces, so that one phase is evenly distributed to another or more phases, so as to achieve the effect of refine homogenization and disperse emulsification .Thus forming a stable liquid-liquid, solid-liquid dispersion status.The working head of the hydraulic lift high shear mixer is refined from stainless steel forgings, and various working head structures can be equipped according to different emulsification requirements. The hydraulic lift high shear mixer is controlled by hydraulic pressure for lifting.

1.Independently developed and designed work head structure, stable operation, low maintenance cost, and easy to clean.

2.Adopt Round-trip engineering oil cylinder to prevent oil leakage.

3.The rotor and stator is made of whole forging material in a CNC machining center , work head with high precision can reach good shear homogenization and emulsification.

4.The material contact parts can be made of stainless steel 304,stainless steel 316L and titanium alloy material.

Hydraulic lift high shear mixer comes with high Precision processing technology,The powerful motor of the pneumatic lift high shear mixer rotates at high speed to generate vacuum condition between the rotor and stator, so materials are sucked into the chamber from the top of the stator& rotor and also from the bottom. Rotor driven by the strong kinetic energy creates high linear speed, which puts the materials under comprehensive action of strong crushing, tearing, centrifugal extrusion, hydraulic friction etc between the precision-engineered gap of the stator and rotor. After processed, the materials are flying out and generate strong turbulence under the action of forces from different direction. Stable emulsion is obtained after repeated disaggregating, dispersing, homogenizing, shearing for a certain period with help of mature production technology and certain quantity emulsifier.

| Model | Power(Kw) | Speed(rpm) | Lifting Method | Lifting Stroke(mm) | Capacity(L) | Dimension(mm) | Weight(Kg) |

| BR-4 | 4 | 0-3000 | Hydraulic Lift | 700 | 30L-100L | 1530*700*1470 | 435 |

| BR-7.5 | 7.5 | 0-3000 | Hydraulic Lift | 700 | 40L-200L | 1530*700*1470 | 495 |

| BR-11 | 11 | 0-3000 | Hydraulic Lift | 900 | 50L-300L | 1820*750*1670 | 650 |

| BR-15 | 15 | 0-3000 | Hydraulic Lift | 900 | 50L-400L | 1820*750*1670 | 730 |

| BR-18.5 | 18.5 | 0-3000 | Hydraulic Lift | 900 | 80L-600L | 1820*750*1670 | 820 |

| BR-22 | 22 | 0-1500 | Hydraulic Lift | 1200 | 80L-600L | 2020*900*2050 | 970 |

| BR-30 | 30 | 0-1500 | Hydraulic Lift | 1200 | 250L-1200L | 2020*900*2050 | 1050 |

| BR-37 | 37 | 0-1500 | Hydraulic Lift | 1200 | 500L-1500L | 2020*900*2050 | 1260 |

| BR-45 | 45 | 0-1000 | Hydraulic Lift | 1400 | 500L-2000L | 2020*1200*2200 | 1580 |

| BR-75 | 75 | 0-1000 | Hydraulic Lift | 1500 | 600L-3000L | 2750*1200*2600 | 2380 |

+86 13966796215 ( Hot Line )

+86 (0)551-67707017 ( Direct Line )

+86 13966796215